MTCY – Motor Test Device Software

MTCY is an ECU (Electronic Control Unit) diagnostic application that supports the UDS (Unified Diagnostic Services) and XCP (Universal Measurement and Calibration Protocol) protocols over the CAN communication bus.

By using database files with ODX (Open Diagnostic eXchange) and A2L (ASAM MCD-2 M) extensions, many services supported by the UDS and XCP universal standard protocols can be used. MTCY offers capabilities that greatly simplify examining diagnostic data on the vehicle, engine, or ECU during both factory and service stages, as well as detecting and tracking errors.

CAPABILITIES

The MTCY application provides the following capabilities based on the current user’s authorization:

-

Reading and writing ECU, vehicle, engine, and sensor identifier information

For example, the engine serial number can be read.

-

Real-time tracking of sensor data and viewing these values through graphs

For example, the current temperature of the ECU can be measured, and its time-based change can be analyzed through a graph.

- Instant modification of vehicle calibration

- Tracking diagnostic error codes with details

- Tracking recorded fault history with details

For example, if a sensor connected to the engine was temporarily disabled and an error history is recorded in the ECU, this situation can be viewed through MTCY.

-

Input-output control of sensors and electronic equipment connected to the engine

For example, the current current flowing through the fans on the vehicle can be modified for diagnostic purposes, or even if the oil sensor is not connected, oil sensor data can still be fed to the ECU.

-

Programming of ECU’s permanent memory

For example, ECU software updates can be performed.

-

Adding new users to the application with specific permissions

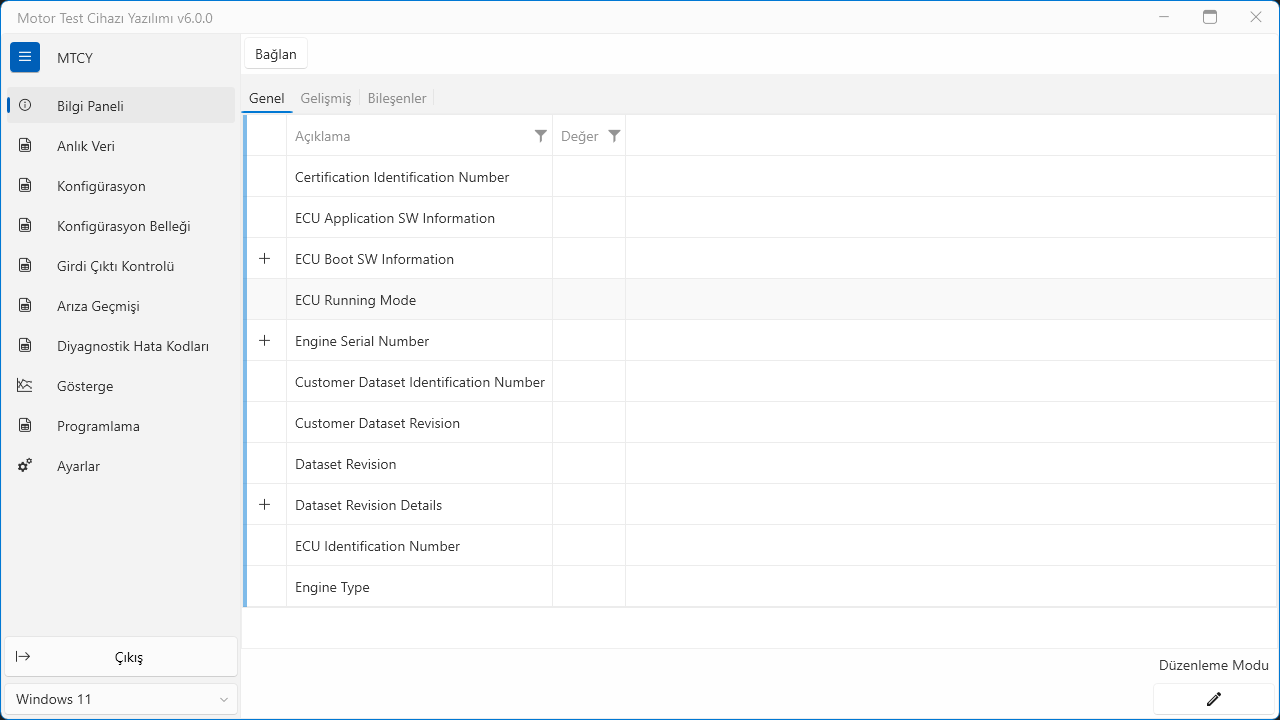

GENERAL INFORMATION PANEL

The ECU, vehicle, engine, and sensor identifier data values can be read. These information values can be permanently modified.

General Information Panel

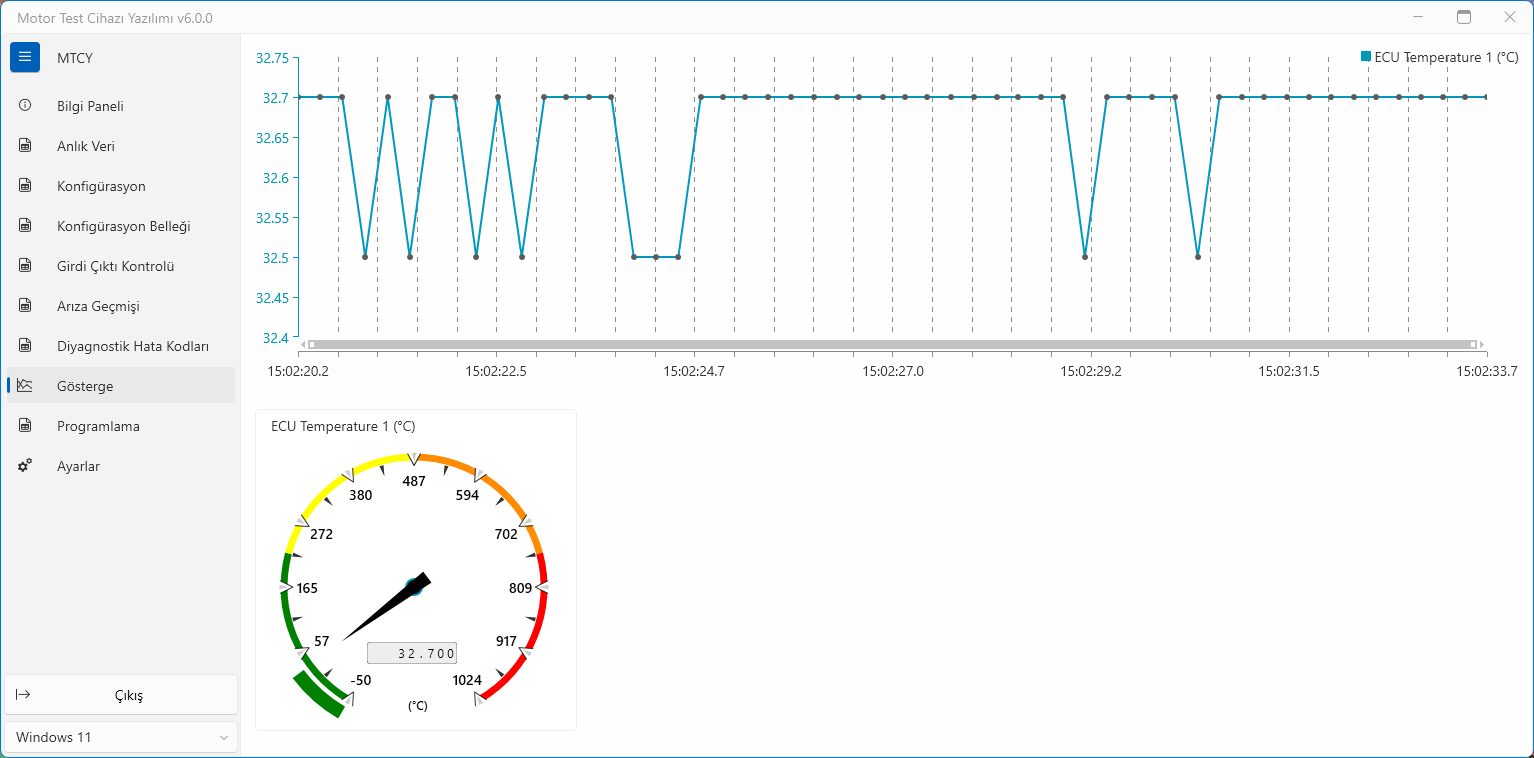

REAL-TIME DATA MONITORING

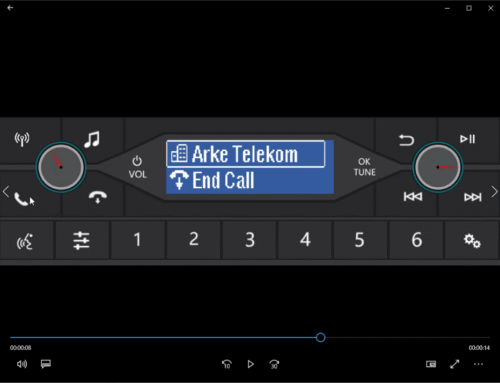

Data related to electronically controlled actuators, sensors, and engine subsystems on the engine can be examined in real-time via MTCY. For these values, graphs or oscilloscope screens can be created to visually track the time-based changes in the data in a rich and detailed manner.

Real-Time Data Monitor

Display Screen

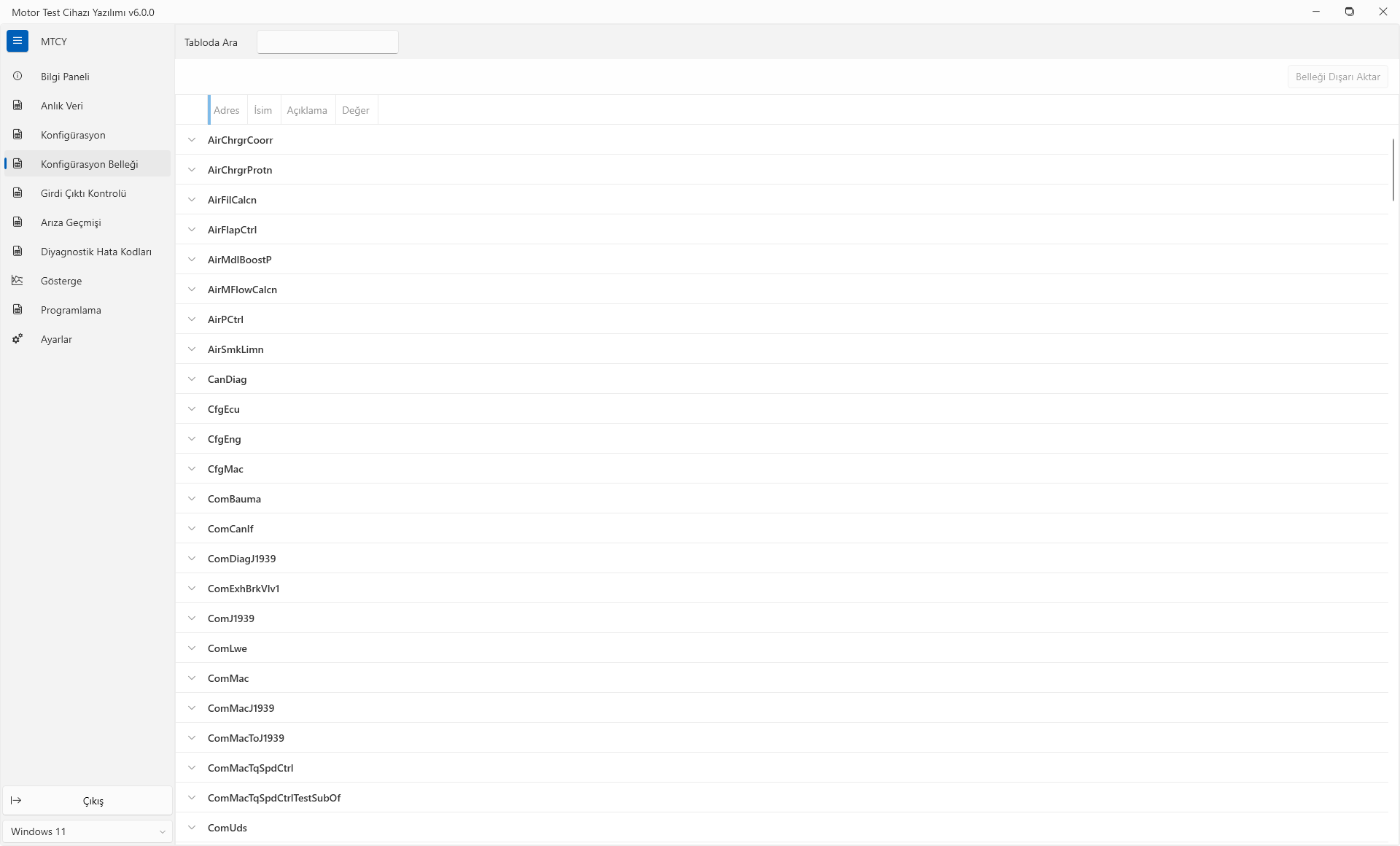

CONFIGURATION/CONFIGURATION MEMORY

With MTCY, calibration values can be read, modified in real-time, or permanently saved to the ECU. It is possible to revert to the calibration values set by the factory, ensuring full control over calibration management on the vehicle. Direct reading from the ECU memory can be performed, and the ECU memory can be exported. This allows the current operational data of the connected ECU to be reported.

Configuration Screen

Configuration Memory Screen

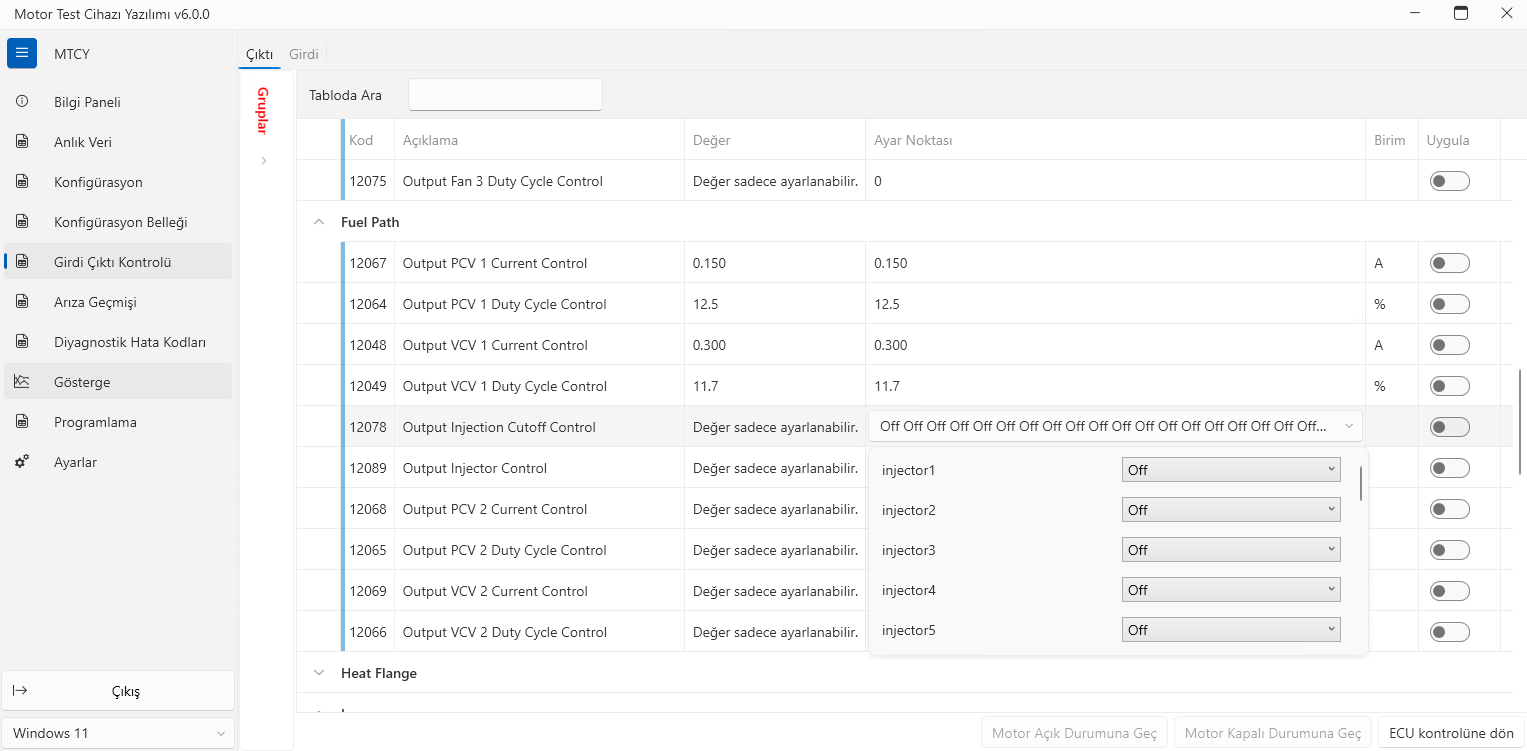

INPUT/OUTPUT CONTROL

Electronically controlled outputs such as actuators, sensors, and engine subsystems on the engine can be tested whether the engine is running or not. For example, injectors can be turned on and off, or the motor fan current can be modified.

Input-related electronic actuators and sensors can be simulated. For instance, even if a temperature sensor that is supposed to be on the engine is not physically present, a temperature value can still be fed to the ECU as input and the vehicle’s response to the fed input can be observed.

Input/Output Control Screen

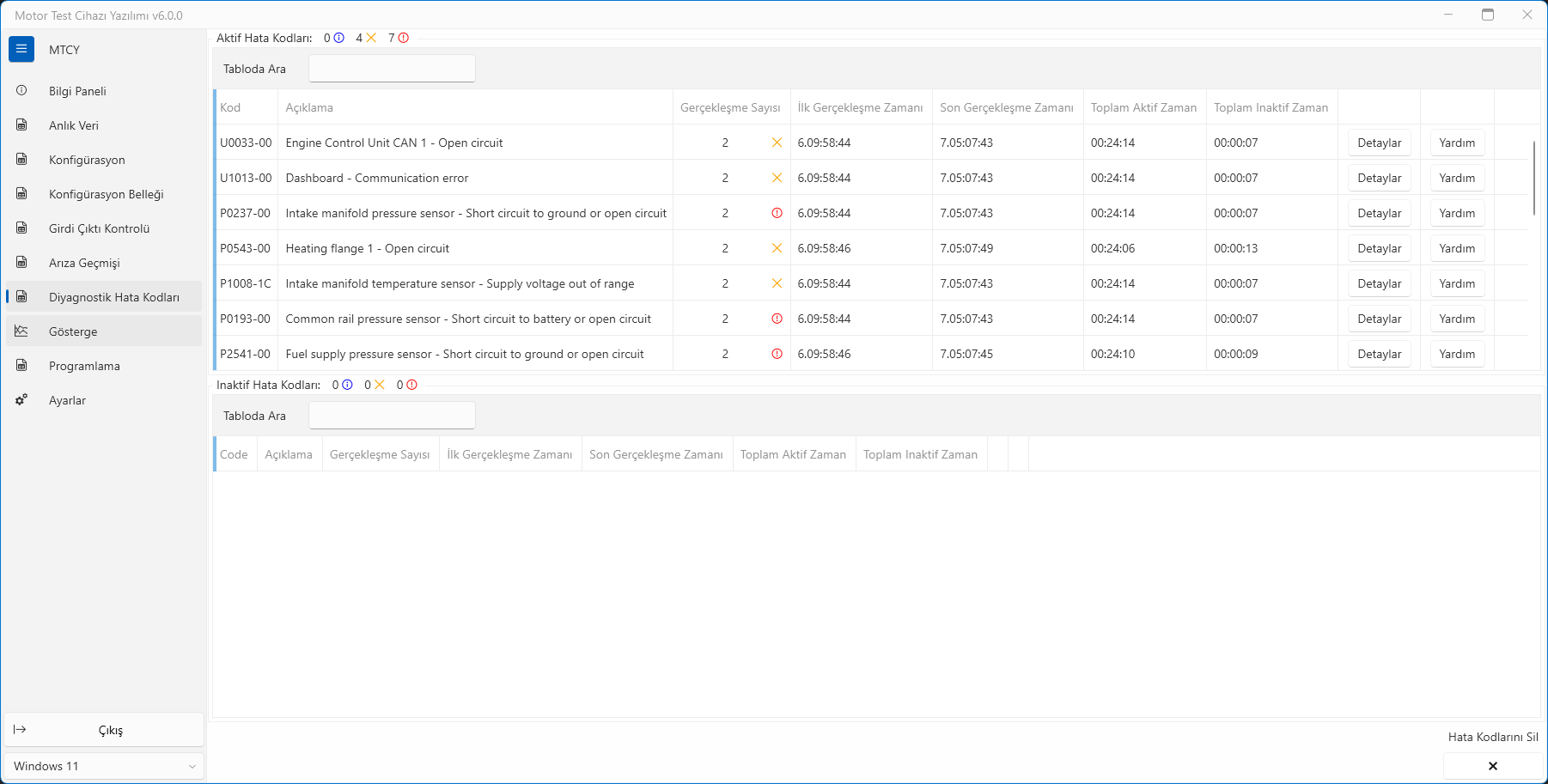

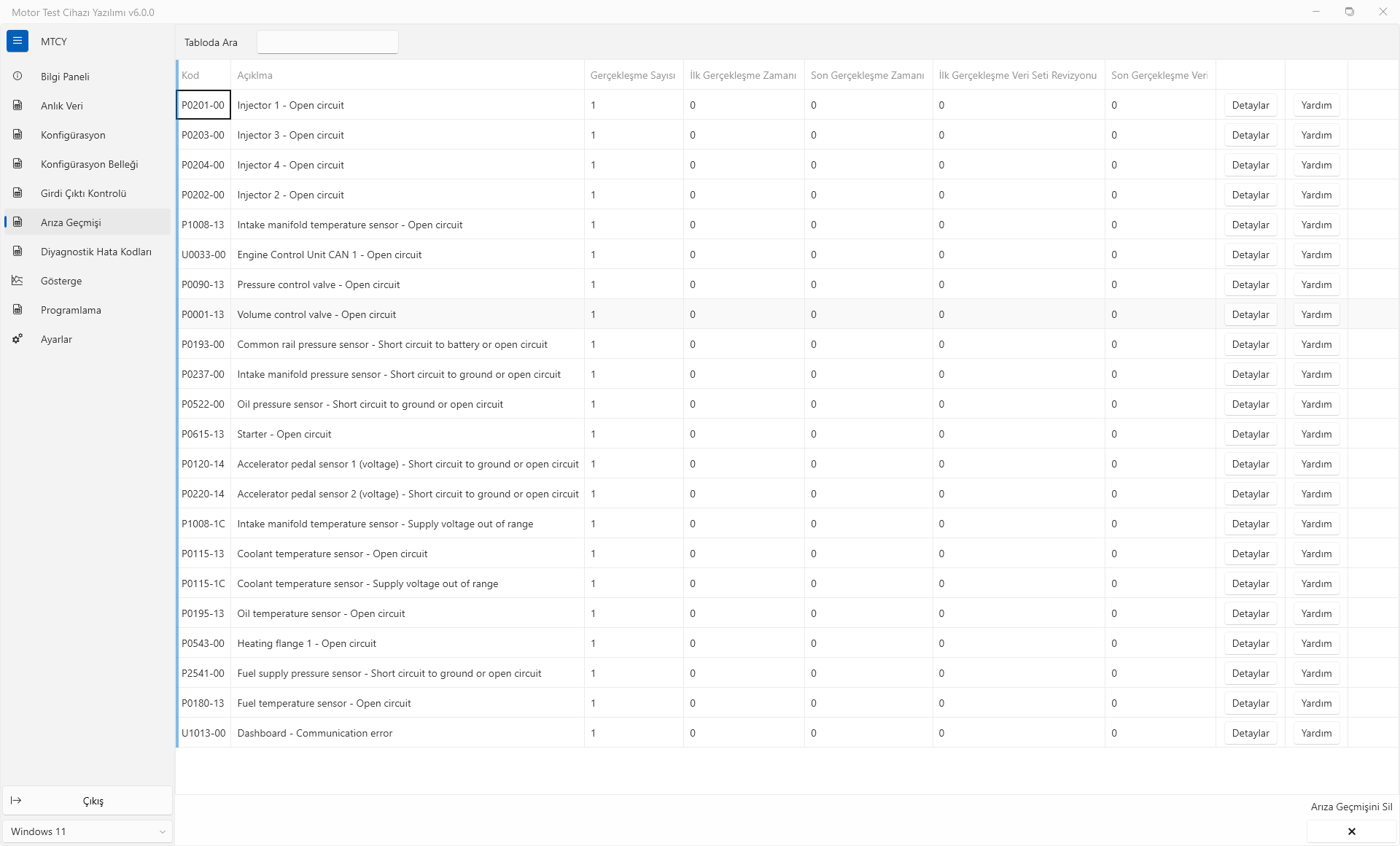

DIAGNOSTIC TROUBLE CODES AND FAULT HISTORY

Current active/passive diagnostic trouble codes can be viewed, and detailed information about these faults can be examined. This allows for easy identification of existing issues or abnormal conditions related to the vehicle. Fault events that occurred during the ECU’s operation, along with their recorded history and details, can also be examined. These records can be permanently deleted if desired.

Diagnostic Dashboard

Fault History Screen